Subpart B - 50th Percentile Male

§ 572.5 General description.

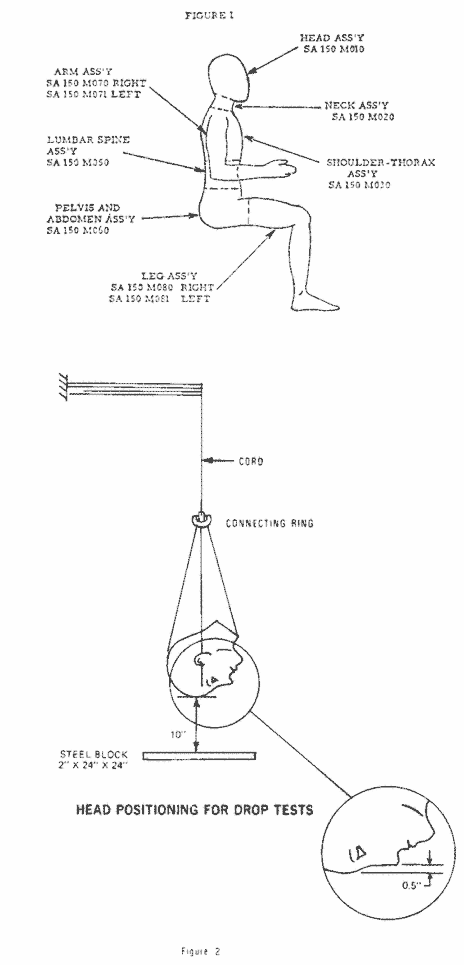

(a) The dummy consists of the component assemblies specified in Figure 1, which are described in their entirety by means of approximately 250 drawings and specifications that are grouped by component assemblies under the following nine headings:

SA 150 M070—Right arm assembly

SA 150 M071—Left arm assembly

SA 150 M050—Lumbar spine assembly

SA 150 M060—Pelvis and abdomen assembly

SA 150 M080—Right leg assembly

SA 150 M081—Left leg assembly

SA 150 M010—Head assembly

SA 150 M020—Neck assembly

SA 150 M030—Shoulder-thorax assembly.

(b) The drawings and specifications referred to in this regulation that are not set forth in full are hereby incorporated in this part by reference. These materials are thereby made part of this regulation. The Director of the Federal Register has approved the materials incorporated by reference. For materials subject to change, only the specific version approved by the Director of the Federal Register and specified in the regulation are incorporated. A notice of any change will be published in the Federal Register. As a convenience to the reader, the materials incorporated by reference are listed in the Finding Aid Table found at the end of this volume of the Code of Federal Regulations.

(c) The materials incorporated by reference are available for examination in Docket 73-08, Docket Section, National Highway Traffic Safety Administration, Room 5109, 400 Seventh Street SW., Washington, DC, 20590. Copies may be obtained from Rowley-Scher Reprographics, Inc., 1216 K Street NW., Washington, DC 20005 ((202) 628-6667). The drawings and specifications are also on file in the reference library of the Office of the Federal Register, National Archives and Records Administration, Washington, DC.

(d) Adjacent segments are joined in a manner such that throughout the range of motion and also under crash impact conditions there is no contact between metallic elements except for contacts that exist under static conditions.

(e) The structural properties of the dummy are such that the dummy conforms to this part in every respect both before and after being used in vehicle tests specified in Standard No. 208 of this chapter (571.208).

(f) A specimen of the dummy is available for surface measurements and access can be arranged by contacting: Office of Vehicle Safety Standards, National Highway Traffic Safety Administration, 400 Seventh Street, SW., Washington, DC 20590.

[50 FR 25423, June 19, 1985]

§ 572.6 Head.

(a) The head consists of the assembly shown as number SA 150 M010 in Figure 1 and conforms to each of the drawings subtended by number SA 150 M010.

(b) When the head is dropped from a height of 10 inches in accordance with paragraph (c) of this section, the peak resultant accelerations at the location of the accelerometers mounted in the head form in accordance with § 572.11(b) shall be not less than 210g, and not more than 260g. The acceleration/time curve for the test shall be unimodal and shall lie at or above the 100g level for an interval not less than 0.9 milliseconds and not more than 1.5 milliseconds. The lateral acceleration vector shall not exceed 10g.

(c) Test procedure:

(1) Suspend the head as shown in Figure 2, so that the lowest point on the forehead is 0.5 inches below the lowest point on the dummy's nose when the midsagittal plane is vertical.

(2) Drop the head from the specified height by means that ensures instant release onto a rigidly supported flat horizontal steel plate, 2 inches thick and 2 feet square, which has a clean, dry surface and any microfinish of not less than 8 microinches (rms) and not more than 80 microinches (rms).

(3) Allow a time period of at least 2 hours between successive tests on the same head.

[38 FR 20451, Aug. 1, 1973, as amended at 42 FR 7152, Feb. 7, 1977]

§ 572.7 Neck.

(a) The neck consists of the assembly shown as number SA 150 M020 in Figure 1 and conforms to each of the drawings subtended by number SA 150 M020.

(b) When the neck is tested with the head in accordance with paragraph (c) of this section, the head shall rotate in reference to the pendulum's longitudinal centerline a total of 68° ±5° about its center of gravity, rotating to the extent specified in the following table at each indicated point in time, measured from impact, with a chordal displacement measured at its center of gravity that is within the limits specified. The chordal displacement at time T is defined as the straight line distance between

(1) the position relative to the pendulum arm of the head center of gravity at time zero, and

(2) the position relative to the pendulum arm of the head center of gravity at time T as illustrated by Figure 3. The peak resultant acceleration recorded at the location of the accelerometers mounted in the head form in accordance with § 572.11(b) shall not exceed 26g. The pendulum shall not reverse direction until the head's center of gravity returns to the original zero time position relative to the pendulum arm.

| Rotation (degrees) | Time (ms) ±(2 + .08T) | Chordal Displacement (inches ±0.5) |

|---|---|---|

| 0 | 0 | 0.0 |

| 30 | 30 | 2.6 |

| 60 | 46 | 4.8 |

| Maximum | 60 | 5.5 |

| 60 | 75 | 4.8 |

| 30 | 95 | 2.6 |

| 0 | 112 | 0.0 |

(c) Test procedure:

(1) Mount the head and neck on a rigid pendulum as specified in Figure 4, so that the head's midsagittal plane is vertical and coincides with the plane of motion of the pendulum's longitudinal centerline. Mount the neck directly to the pendulum as shown in Figure 4.

(2) Release the pendulum and allow it to fall freely from a height such that the velocity at impact is 23.5 ±2.0 feet per second (fps), measured at the center of the accelerometer specified in Figure 4.

(3) Decelerate the pendulum to a stop with an acceleration-time pulse described as follows:

(i) Establish 5g and 20g levels on the a-t curve.

(ii) Establish t1 at the point where the rising a-t curve first crosses the 5g level, t2 at the point where the rising a-t curve first crosses the 20g level, t2 at the point where the decaying a-t curve last crosses the 20g level, and t4 at the point where the decaying a-t curve first crosses the 5g level.

(iii) t2-t1 shall be not more than 3 milliseconds.

(iv) t3-t2 shall be not less than 25 milliseconds and not more than 30 milliseconds.

(v) t4-t3 shall be not more than 10 milliseconds.

(vi) The average deceleration between t2 and t3 shall be not less than 20g and not more than 24g.

(4) Allow the neck to flex without impact of the head or neck with any object other than the pendulum arm.

[38 FR 20451, Aug. 1, 1973, as amended at 42 FR 7152, Feb. 7, 1977; 42 FR 12176, Mar. 3, 1977; 45 FR 40596, June 16, 1980]

§ 572.8 Thorax.

(a) The thorax consists of the assembly shown as number SA 150 M030 in Figure 1, and conforms to each of the drawings subtended by number SA 150 M030.

(b) The thorax contains enough unobstructed interior space behind the rib cage to permit the midpoint of the sternum to be depressed 2 inches without contact between the rib cage and other parts of the dummy or its instrumentation, except for instruments specified in paragraph (d)(7) of this section.

(c) When impacted by a test probe conforming to § 572.11(a) at 14 fps and at 22 fps in accordance with paragraph (d) of this section, the thorax shall resist with forces measured by the test probe of not more than 1450 pounds and 2250 pounds, respectively, and shall deflect by amounts not greater than 1.1 inches and 1.7 inches, respectively. The internal hysteresis in each impact shall not be less than 50 percent and not more than 70 percent.

(d) Test procedure:

(1) With the dummy seated without back support on a surface as specified in § 572.11(i) and in the orientation specified in § 572.11(i), adjust the dummy arms and legs until they are extended horizontally forward parallel to the midsagittal plane.

(2) Place the longitudinal center line of the test probe so that it is 17.7 ±0.1 inches above the seating surface at impact.

(3) Align the test probe specified in § 572.11(a) so that at impact its longitudinal centerline coincides within 2 degrees of a horizontal line in the dummy's midsagittal plane.

(4) Adjust the dummy so that the surface area on the thorax immediately adjacent to the projected longitudinal center line of the test probe is vertical. Limb support, as needed to achieve and maintain this orientation, may be provided by placement of a steel rod of any diameter not less than one-quarter of an inch and not more than three-eighths of an inch, with hemispherical ends, vertically under the limb at its projected geometric center.

(5) Impact the thorax with the test probe so that its longitudinal centerline falls within 2 degrees of a horizontal line in the dummy's midsagittal plane at the moment of impact.

(6) Guide the probe during impact so that it moves with no significant lateral, vertical, or rotational movement.

(7) Measure the horizontal deflection of the sternum relative to the thoracic spine along the line established by the longitudinal centerline of the probe at the moment of impact, using a potentiometer mounted inside the sternum.

(8) Measure hysteresis by determining the ratio of the area between the loading and unloading portions of the force deflection curve to the area under the loading portion of the curve.

[38 FR 20451, Aug. 1, 1973, as amended at 42 FR 7152, Feb. 7, 1977]

§ 572.9 Lumbar spine, abdomen, and pelvis.

(a) The lumbar spine, abdomen, and pelvis consist of the assemblies designated as numbers SA 150 M050 and SA 150 M060 in Figure 1 and conform to the drawings subtended by these numbers.

(b) When subjected to continuously applied force in accordance with paragraph (c) of this section, the lumbar spine assembly shall flex by an amount that permits the rigid thoracic spine to rotate from its initial position in accordance with Figure 11 by the number of degrees shown below at each specified force level, and straighten upon removal of the force to within 12 degrees of its initial position in accordance with Figure 11.

| Flexion (degrees) | Force (±6 pounds) |

|---|---|

| 0 | 0 |

| 20 | 28 |

| 30 | 40 |

| 40 | 52 |

(c) Test procedure:

(1) Assemble the thorax, lumbar spine, pelvic, and upper leg assemblies (above the femur force transducers), ensuring that all component surfaces are clean, dry, and untreated unless otherwise specified, and attach them to the horizontal fixture shown in Figure 5 at the two link rod pins and with the mounting brackets for the lumbar test fixtures illustrated in Figures 6 to 9.

(2) Attach the rear mounting of the pelvis to the pelvic instrument cavity rear face at the four 1⁄4″ cap screw holes and attach the front mounting at the femur axial rotation joint. Tighten the mountings so that the pelvic-lumbar adapter is horizontal and adjust the femur friction plungers at each hip socket joint to 240 inch-pounds torque.

(3) Flex the thorax forward 50° and then rearward as necessary to return it to its initial position in accordance with Figure 11 unsupported by external means.

(4) Apply a forward force perpendicular to the thorax instrument cavity rear face in the midsagittal plane 15 inches above the top surface of the pelvic-lumbar adapter. Apply the force at any torso deflection rate between .5 and 1.5 degrees per second up to 40° of flexion but no further, continue to apply for 10 seconds that force necessary to maintain 40° of flexion, and record the force with an instrument mounted to the thorax as shown in Figure 5. Release all force as rapidly as possible and measure the return angle 3 minutes after the release.

(d) When the abdomen is subjected to continuously applied force in accordance with paragraph (e) of this section, the abdominal force-deflection curve shall be within the two curves plotted in Figure 10.

(e) Test procedure:

(1) Place the assembled thorax, lumbar spine and pelvic assemblies in a supine position on a flat, rigid, smooth, dry, clean horizontal surface, ensuring that all component surfaces are clean, dry, and untreated unless otherwise specified.

(2) Place a rigid cylinder 6 inches in diameter and 18 inches long transversely across the abdomen, so that the cylinder is symmetrical about the midsagittal plane, with its longitudinal centerline horizontal and perpendicular to the midsagittal plane at a point 9.2 inches above the bottom line of the buttocks, measured with the dummy positioned in accordance with Figure 11.

(3) Establish the zero deflection point as the point at which a force of 10 pounds has been reached.

(4) Apply a vertical downward force through the cylinder at any rate between 0.25 and 0.35 inches per second.

(5) Guide the cylinder so that it moves without significant lateral or rotational movement.

[42 FR 7152, Feb. 7, 1977]

§ 572.10 Limbs.

(a) The limbs consist of the assemblies shown as numbers SA 150 M070, SA 150 M071, SA 150 M080, and SA 150 M081 in Figure 1 and conform to the drawings subtended by these numbers.

(b) When each knee is impacted at 6.9 ft/sec. in accordance with paragraph (c) of this section, the maximum force on the femur shall be not more than 2500 pounds and not less than 1850 pounds, with a duration above 1000 pounds of not less than 1.7 milliseconds.

(c) Test procedure:

(1) Seat the dummy without back support on a surface as specified in § 572.11(i) that is 17.3 ±0.2 inches above a horizontal surface, oriented as specified in § 572.11(i), and with the hip joint adjustment at any setting between 1g and 2g. Place the dummy legs in planes parallel to its midsagittal plane (knee pivot centerline perpendicular to the midsagittal plane) and with the feet flat on the horizontal surface. Adjust the feet and lower legs until the lines between the midpoints of the knee pivots and the ankle pivots are at any angle not less than 2 degrees and not more than 4 degrees rear of the vertical, measured at the centerline of the knee pivots.

(2) Reposition the dummy if necessary so that the rearmost point of the lower legs at the level one inch below the seating surface remains at any distance not less than 5 inches and not more than 6 inches forward of the forward edge of the seat.

(3) Align the test probe specified in § 572.11(a) so that at impact its longitudinal centerline coincides within ±2° with the longitudinal centerline of the femur.

(4) Impact the knee with the test probe moving horizontally and parallel to the midsagittal plane at the specified velocity.

(5) Guide the probe during impact so that it moves with no significant lateral, vertical, or rotational movement.

[38 FR 20451, Aug. 1, 1973, as amended at 42 FR 7153, Feb. 7, 1977]

§ 572.11 Test conditions and instrumentation.

(a) The test probe used for thoracic and knee impact tests is a cylinder 6 inches in diameter that weighs 51.5 pounds including instrumentation. Its impacting end has a flat right face that is rigid and that has an edge radius of 0.5 inches.

(b) Accelerometers are mounted in the head on the horizontal transverse bulkhead shown in the drawings subreferenced under assembly No. SA 150 M010 in Figure 1, so that their sensitive axes intersect at a point in the midsagittal plane 0.5 inches above the horizontal bulkhead and 1.9 inches ventral of the vertical mating surface of the skull with the skull cover. One accelerometer is aligned with its sensitive axis perpendicular to the horizontal bulkhead in the midsagittal plane and with its seismic mass center at any distance up to 0.3 inches superior to the axial intersection point. Another accelerometer is aligned with its sensitive axis parallel to the horizontal bulkhead and perpendicular to the midsagittal plane, and with its seismic mass center at any distance up to 1.3 inches to the left of the axial intersection point (left side of dummy is the same as that of man). A third accelerometer is aligned with its sensitive axis parallel to the horizontal bulkhead in the midsagittal plane, and with its seismic mass center at any distance up to 1.3 inches dorsal to the axial intersection point.

(c) Accelerometers are mounted in the thorax by means of a bracket attached to the rear vertical surface (hereafter “attachment surface”) of the thoracic spine so that their sensitive axes intersect at a point in the midsagittal plane 0.8 inches below the upper surface of the plate to which the neck mounting bracket is attached and 3.2 inches perpendicularly forward of the surface to which the accelerometer bracket is attached. One accelerometer has its sensitive axis oriented parallel to the attachment surface in the midsagittal plane, with its seismic mass center at any distance up to 1.3 inches inferior to the intersection of the sensitive axes specified above. Another accelerometer has its sensitive axis oriented parallel to the attachment surface and perpendicular to the midsagittal plane, with its seismic mass center at any distance up to 0.2 inches to the right of the intersection of the sensitive axes specified above. A third accelerometer has its sensitive axis oriented perpendicular to the attachment surface in the midsagittal plane, with its seismic mass center at any distance up to 1.3 inches dorsal to the intersection of the sensitive axes specified above. Accelerometers are oriented with the dummy in the position specified in § 572.11(i).

(d) A force-sensing device is mounted axially in each femur shaft so that the transverse centerline of the sensing element is 4.25 inches from the knee's center of rotation.

(e) The outputs of acceleration and force-sensing devices installed in the dummy and in the test apparatus specified by this part are recorded in individual data channels that conform to the requirements of SAE Recommended Practice J211a, December 1971, with channel classes as follows:

(1) Head acceleration—Class 1000.

(2) Pendulum acceleration—Class 60.

(3) Thorax acceleration—Class 180.

(4) Thorax compression—Class 180.

(5) Femur force—Class 600.

(f) The mountings for sensing devices have no resonance frequency within a range of 3 times the frequency range of the applicable channel class.

(g) Limb joints are set at 1g, barely restraining the weight of the limb when it is extended horizontally. The force required to move a limb segment does not exceed 2g throughout the range of limb motion.

(h) Performance tests are conducted at any temperature from 66 °F to 78 °F and at any relative humidity from 10 percent to 70 percent after exposure of the dummy to these conditions for a period of not less than 4 hours.

(i) For the performance tests specified in §§ 572.8, 572.9, and 572.10, the dummy is positioned in accordance with Figure 11 as follows:

(1) The dummy is placed on a flat, rigid, smooth, clean, dry, horizontal, steel test surface whose length and width dimensions are not less than 16 inches, so that the dummy's midsagittal plane is vertical and centered on the test surface and the rearmost points on its lower legs at the level of the test surface are at any distance not less than 5 inches and not more than 6 inches forward of the forward edge of the test surface.

(2) The pelvis is adjusted so that the upper surface of the lumbar-pelvic adapter is horizontal.

(3) The shoulder yokes are adjusted so that they are at the midpoint of their anterior-posterior travel with their upper surfaces horizontal.

(4) The dummy is adjusted so that the rear surfaces of the shoulders and buttocks are tangent to a transverse vertical plane.

(5) The upper legs are positioned symmetrically about the midsagittal plane so that the distance between the knee pivot bolt heads is 11.6 inches.

(6) The lower legs are positioned in planes parallel to the midsagittal plane so that the lines between the midpoint of the knee pivots and the ankle pivots are vertical.

(j) The dummy's dimensions, as specified in drawing number SA 150 M002, are determined as follows:

(1) With the dummy seated as specified in paragraph (i) of this section, the head is adjusted and secured so that its occiput is 1.7 inches forward of the transverse vertical plane with the vertical mating surface of the skull with its cover parallel to the transverse vertical plane.

(2) The thorax is adjusted and secured so that the rear surface of the chest accelerometer mounting cavity is inclined 3° forward of vertical.

(3) Chest and waist circumference and chest depth measurements are taken with the dummy positioned in accordance with paragraphs (j) (1) and (2) of this section.

(4) The chest skin and abdominal sac are removed and all following measurements are made without them.

(5) Seated height is measured from the seating surface to the uppermost point on the head-skin surface.

(6) Shoulder pivot height is measured from the seating surface to the center of the arm elevation pivot.

(7) H-point locations are measured from the seating surface to the center of the holes in the pelvis flesh covering in line with the hip motion ball.

(8) Knee pivot distance from the backline is measured to the center of the knee pivot bolt head.

(9) Knee pivot distance from floor is measured from the center of the knee pivot bolt head to the bottom of the heel when the foot is horizontal and pointing forward.

(10) Shoulder width measurement is taken at arm elevation pivot center height with the centerlines between the elbow pivots and the shoulder pivots vertical.

(11) Hip width measurement is taken at widest point of pelvic section.

(k) Performance tests of the same component, segment, assembly, or fully assembled dummy are separated in time by a period of not less than 30 minutes unless otherwise noted.

(l) Surfaces of dummy components are not painted except as specified in this part or in drawings subtended by this part.

[38 FR 20451, Aug. 1, 1973, as amended at 42 FR 7153, Feb. 7, 1977]